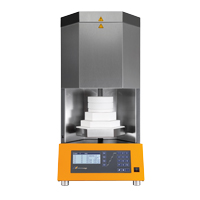

Sintering furnaces

Technicle Data:

| Dimensions (W x H x D) | 400 x 600 x 400 mm |

| Capacity |

2 x Ø 120 mm sintering bowl (up to 50 single crowns) |

| Max. Temperature | 1650 °C |

| Weight | 55 kg |

| Supply voltage range | 200 - 240 V (± 10% deviation) |

| Frequency | 50/60 Hz |

| Power max. | 1,3 kW |

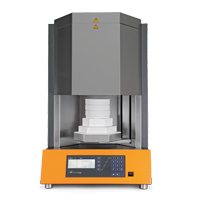

The redesigned HTS-2 model series combines the well-known features of the models HT-S and HT-S SPEED.

The HTS-2 offers you not only the fusion of the properties of old models, but also a larger sintering capacity of up to 80 individual crowns. The heating system with four highperformance molybdenum disilicide heating elements (MoSi2) means that you can now choose whether to use the conventional long-term sintering or the SPEED-sintering with a heat-up rate up to 99°C/minute.

The simple, practical handling of the HT-series program control was also incorporated here with all its familiar functions; program display on a four-line LCD-display, timer function for sintering overnight or also using drying programs for wet-milled restorations. There are three service programs for servicing the heating chamber and the heating system.

HT-2 - even more efficient due to a larger capacity

Due to the size of the heating chamber, it is now possible to process three sintering trays Ø= 120mm during the conventional long-term sintering. However, the heating system with six high-quality molybdenum disilicide heating elements (MoSi2) enable you to carry out processes within 76 minutes in a SPEED-sintering process. These represent optimal prerequisites for your dental laboratory or milling centre.

As with all our model variants, the HT-2 is operated with a simple, self-explanatory program control. 4-line LCD-display, timer function for overnight sintering, drying programs for wet-milled restorations. There are three service programs for servicing the heating chamber and the heating system.

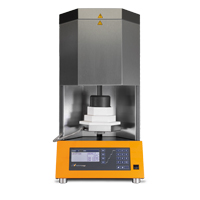

Safe and fit for the future

There are three models available to select from for sintering non-precious metal (NEM). All of these models work under inert gas atmosphere to protect the nonprecious metal from scaling.

Choose from two long-lasting non-precious metal sintering systems. For the metal system 100, the shieldinggas supply is system-controlled. In addition to some preset material parameters, free programs are available. This guarantees safety. For the metal system 120, on the other hand, the shielding-gas supply can be adjusted manually. In addition to a high level of safety the customer can be sure to have the freedom to adapt the system to new kinds of metal material in the future.