HinriMill milling machines

Digitize your practice with the HinriMill e4. You and your patients can benefit from restorations in just one session of treatment

The new HinriMill e4 makes it so easy for you to get started with chairside production of dental restorations, and gives you maximum freedom. Combine the HinriMill e4 with your preferred intraoral scanner, any CAD software and materials that are appropriate for your individual patients. The HinriMill e4 is the heart of your workflow and produces the perfect restoration for you.

The integrated CAM software enables you to get started right away!

RELIABILITY MEETS PRECISION.

Developed and manufactured entirely in Germany, the HinriMill e4 guarantees impressive manufacturing results and optimum reliability. Despite its compact design, the machine comprises only high-quality industrial components in the housing.

With a machine weight of only 28 kg and no use of compressed air, the HinriMill e4 offers maximum flexibility in terms of installation. You can set the HinriMill e4 anywhere.

True to the motto: unpack, connect, start milling!

Innovative

- No compressed air required with the patent-pending AIRTOOL

- Machine design optimized for minimal weight

- Multi-compartment for cooling liquid tank or optional dry milling container

- Modular machine design to optimize servicing and maintenance

Reliable

- 100% developed and manufactured in Germany

- Optimum manufacturing results and high durability with only premium-quality industrial components

Fast & precise

- 800 W 60,000 rpm spindle

- 3 μm repetition accuracy

- Sturdy aluminum welded construction

Independent

- DENTALCAM software with open interface to CAD software and materials

- Virtually any intraoral scanners can be used

- Grinds and mills almost all block materials up to 45 mm long from numerous manufacturers

- A full range of materials for glass ceramics, composites, zirconia and plastic

The HinriMill e5 requires no compressed air; therefore, you have maximum freedom in the choice of the installation site, and you also benefit from minimal operating costs. The open system architecture of the HinriMill e5 makes your entry into the digital production of dental restorations quick and easy, and it fits perfectly into your workflows. The integrated CAM software enables you to get started right away!

Plug & Mill: Unpack, connect, start milling!

No compressed air needed - due to AIRTOOL.

One great innovation of the HinriMill e5 is that it does not use compressed air: The HinriMill e5 requires neither an external compressed air connection nor an integrated compressor, which is only possible with our patent-pending AIRTOOL. The AIRTOOL turbine blades use the speed of the high-frequency spindle to generate a powerful air flow, which keeps the workpiece free from dust and chippings. They are removed by vacuum from a dust collector

Innovative

- No compressed air required with the patent-pending AIRTOOL

- Machine design optimized for minimal weight

- C-holder for 90° machining of anterior teeth (coming soon)

- Modular machine design to optimize servicing and maintenance

Reliable

- 100% developed and manufactured in Germany

- Optimum manufacturing results and high durability with only premium-quality industrial components

Fast & precise

- 800 W 60,000 rpm spindle

- 3 μm repetition accuracy

- Cast aluminum body for low vibration in operation

Independent

- Mills almost all materials up to CoCr sintered metals in a 98.5 mm disc format, holders available for 110 mm discs and blocks

- Maximum indication versatility with a rotating angle of ±35° in the 5 th axis and blanks with a thickness of up to 40 mm

- DENTALCAM software with open interface to all scanners and materials

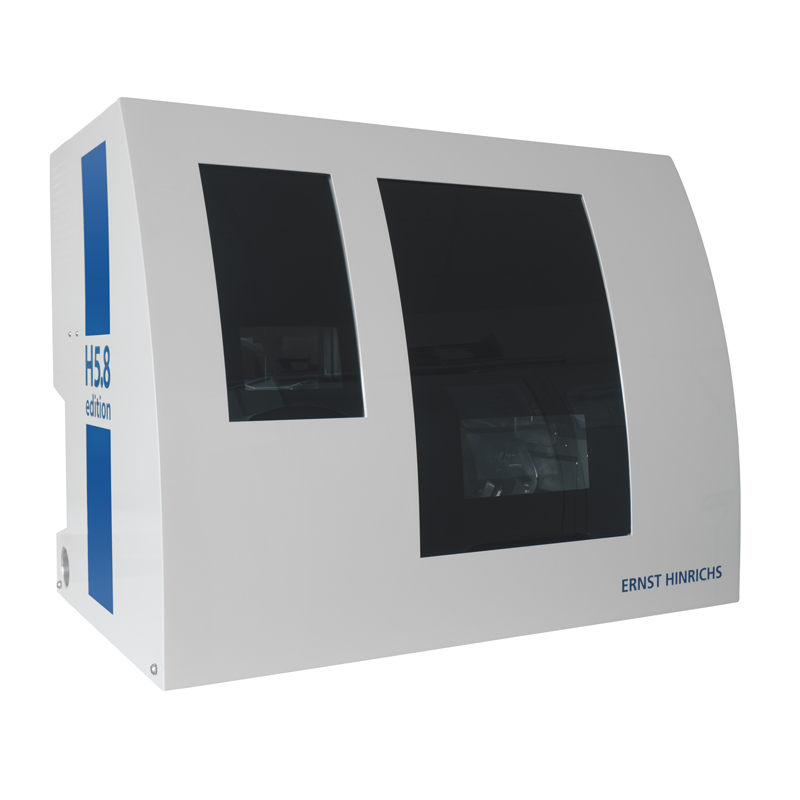

With the new high-end HinriMill R5 dental lab machine, ERNST HINRICHS Dental offers a highly automated milling and grinding machine with a tenfold blank changer for both wet and dry machining, bringing revolutionary approaches to the lab. It combines utmost precision with maximum stability regardless of material – all with a minimal footprint.

Operating the machine is also incredibly simple thanks to various technologies: With Direct Disc Technology, milling blanks can now be processed directly without any cumbersome fiddling with the tenter frames. Like all ERNST HINRICHS Dental machines, the HinriMill R5 can be used with a maximum variety of materials from all manufacturers when it comes to discs, blocks and abutments and therefore provides perfect investment protection!

Direct Clean Technology allows you to conveniently switch between wet and dry machining. In addition to integrated ionizers and active workspace ventilation, the HinriMill R5 also has a highly intelligent drying feature.

Another novelty is the integrated water cooling, which significantly minimizes the thermal expansion of the spindle and Z axis. Faster machining with even more consistent results and longer spindle lifes are the benefits for future HinriMill R5 owners.

The ability to feed milling blanks up to 40 mm thickness via a blank changer and get right to work is another highlight. Even better is the generous tilt angle for the fifth axis of ±?35 degrees. The R5 thereby guarantees a maximum of indication variety and freedom of design.

5 simultaneously working axes

The second rotary axis (B axis) with a rotation range of up to ± 30 degrees enables you to mill undercuts and so opens up new machining possibilities.

blank changer for 8 blanks

You fit the changing station with blanks via a smaller additional front cover. The proper blank for your milling job is inserted into the fixing device automatically when required. So the machine can mill around the clock and no operation steps have to be performed.

wide range of materials and indications

Machining of plastics, wax, PEEK, zirconium oxide and composites up to non-precious alloys on cobalt-chrome basis, titanium and glass ceramics. For crowns, bridges (also fully anatomical), inlays, onlays, abutments, telescope crowns, model plates, model casts, bite splints, model plug-in teeth, implant bars, veneers, table-tops, etc.

worldwide applicable

Due to far range switching mode power supply for 100 – 240 V and 50/60 Hz with country-specifi c mains plug. Certification according to ANSI/UL 61010-1 for the USA and Canada.

powerful and highly precise synchronous spindle

With 4-fold hybrid ceramic ball bearings and a nominal power of 300 W under continuous load.

optional wet grinding module

Both machines are prepared for connecting the wet grinding module. There are liquid nozzles already mounted at the spindle so that the tool will be optimally cooled while grinding. Thus you can also process glass ceramics.

machine bed of massive aluminium cast

Thus these machines gain much stability at minimal exterior dimensions. Moreover, vibrations are reduced and the mechanics is optimally protected.

no previous knowledge necessary

Very easy operation via provided CAM software DentalCAM with Direct-Mill function – no previous knowledge in milling and grinding necessary.

sophisticated protective mechanisms

Protection of the danger zone during the machining process due to an automatic safety interlock at the frontcover. Protection of the mechanics against dust and chippings as well as reduced wearing and maintenance effort due to integrated working chamber sealing air concept.

Easy to use

- smart touchscreen operation

- automatic working chamber access door

- tool-free material mount (1-click mounting)

- coloured working chamber illumination indicates machining status

- working chamber with anti-graffiti coating for minimum cleaning effort

- automatic tool change

- self-opening drawer without handle contains water tank and tool magazines

- colour coded tool magazine

- removable and dishwasher-proof water tank

- integrated WiFi module

Quality

- most finely balanced high frequency spindle with up to 100,000 RPM

- precise guiding rails and high-class ballscrew drives

- massive internal machine bed made of aluminium cast

- state-of-the-art FPGA based controller

- premium industrial quality Made in Germany

Safety

- automatic matching of block material and required tool magazine

- no unauthorised interference by patients possible

- webcam in the working chamber

Materials

- glass ceramics

- PMMA

- zirconium oxide

- composites

- prefabricated titanium abutments

Environment & Resources

- extremely quiet due to internal insulation and thick-walled die casting housing

- no external compressed air supply necessary

- grinding without additives subject to mandatory waste disposal

- 5 simultaneously working axes

- rotation range up to ± 35 degrees

- blanks of up to 40 mm thickness

- machine bed of massive aluminium cast

- automatic changer for 16 tools

- powerful and highly precise synchronous spindle

- sophisticated protective mechanisms

- practical drawer for accessories

4 simultaneously working axes

The rotary axis (A axis) has a rotation range of + 190° to 10°.

fully integrated liquid cooling system

Closed liquid cooling system – no external module for pump etc. necessary. Comfortable filling and cleaning due to removable drawer for liquid tank and filter for separating grinding particles.

automatic changer for 8 tools

The two removable changer stations for four tools each will be equipped with just a few moves. The material will then be machined fully automatized and you can spend your time with other useful things until you remove the finished work. Haptic tool measurement for usage of diamond-coated tools.

worldwide applicable

Due to far range switching mode power supply for 100 – 240 V and 50/60 Hz with country-specific mains plug. Certification according to ANSI/UL61010-1 for the USA and Canada.

powerful and highly precise spindle

With 4-fold hybrid ceramic ball bearings and a nominal power of 300 W under continuous load.

wide range of indications

For crowns, bridges (also fully anatomical), inlays, onlays, abutments, telescope crowns, veneers, table-tops etc.

machine bed of massive aluminium cast

The machine bed of massive aluminium cast facilitates highest stability and a low-vibration operation.

no previous knowledge necessary

Very easy operation via provided CAM software DentalCAM with machining strategies that are especially adapted for grinding – no previous knowledge in milling or grinding necessary.

sophisticated protective mechanisms

Protection of the danger zone during the machining process with an automatic safety interlock at the frontcover. A flexible rubber gaiter protects mechanics, electronics and spindle eff ectively from humidity.

ideal for labor/practice lab

The HinriMilll N4 Edition is an ideal machine for practice laboratories for producing the works without time delay and higher costs for an external production. Or you specifically add the wet grinding machine HinriMill N4 Edition to the already existing machines for dry processing in the dental

laboratory and save the cleaning works.

Proven quality now even better: with the new HinriMill T5 Edition you will achieve perfect dry milling results. Process an especially wide range of indications and material (blanks up to 40 mm) with 5 axes. Revolutionary technology, such as a tool-free blank clamping and a built-in ionizer will help you in doing so.

The new HinriMill T5 Edition is equipped with the innovative DirectDiscTechnology for securing disks. Thanks to this tool-free blank clamping system, the machine can be loaded with material even more quicker and easier.

A built-in ionizer neutralizes the static charge of acrylic particles and an improved air circulation in the working area also significantly reduces cleaning time. But that’s not all – one more convincing highlight of this dry milling machine includes a built-in camera for simplified support.

An Ethernet port increases the stability and flexibility of the connection at the machine’s installation location.

Unparalleled precision

- restorations in ultra HD

- premium spindle with 4-fold hybrid ceramic ball bearings for highest running accuracy

- 3 microns repetition accuracy

Powerful and robust

- mills the toughest materials on the market, incl. CoCr

- powerful 500 watt spindle and 60,000 rpm

- heavy industrial quality for maximum stiffness

- solid cast body for the lowest vibrations

Maximum independence

- unlimited material accessibility in 98 mm disc format, separate block and prefab abutment holders available

- covers the broadest range of indications, due to ± 35° rotation angle in the 5th axis, and up to 40 mm blanks

Proven German reliability

- 100% engineered and manufactured in Germany

- sophisticated sealing air concept to protect mechanics, electronics, and spindle

- webcam for remote support

- ethernet for stable long-range connection

Extremely economical

- ionizer and improved air circulation for easy machine cleaning

- DirectDiscTechnology for revolutionary disc clamping

- automatic changer for 16 tools

- perfectly matched DentalCAM software included in price